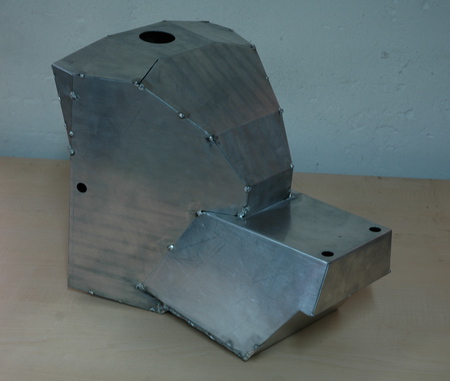

This is the first prototype of the Moto2 fueltank, made in aluminium. As you can see in the photo, it hasn’t been welded yet, with the intention of checking that it fits properly in the bike, before welding it.

I designed it trying to make it very narrow, in that way the rider can close a little bit more his legs, making possible to reduce a little bit the front area of the bike in order to make it more aerodynamic. I also tried to make a “low” fueltank, in this way the rider can lie down over it in a more comfortable way, again with the intention of improving the aerodynamics.

In order to try to make a lower and narrower fueltank I used the Honda CBR one as a reference.

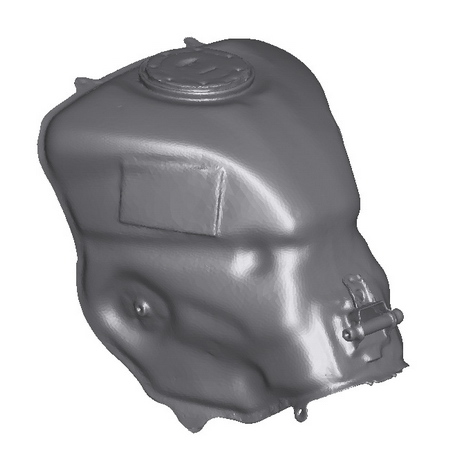

Like you know one of our technical sponsors is Incomet, a company that provides us with scanning service. Taking the most of it I asked them to scan the Honda fueltank. This is how it looks the mesh that you obtain from the point cloud that is gererated in the scanning process.

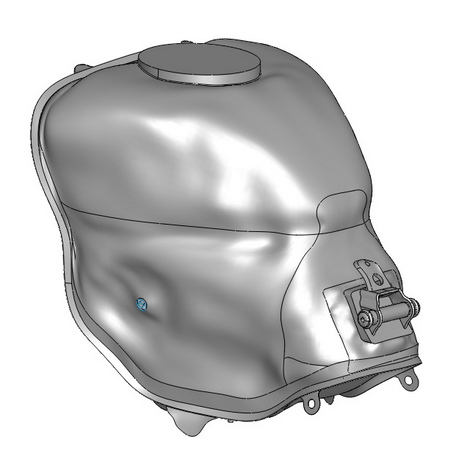

And this is how it looks once you convert the mesh into surfaces. This work could have been done in a much more precise way, but it’s not worth doing it because as I said I only wanted it as a reference to design the Moto2 fueltank.

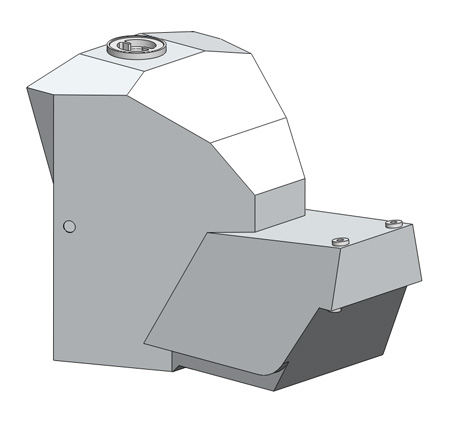

Finally here you can see the final design of the fueltank. As it happens with the original one, this fueltank is covered by a fiber carcass. In following evolutions of the bike it is probable that we will make a “seen” (not covered) fueltank, eliminating the carcass and taking more profit of the available room.

Because the fueltak is narrower and lower than the Honda CBR one, part of the fuel has gone under the rider seat.

The cut that you can see in the lower area of the fueltank has been made to let room for the electrical loom.

Stay tuned! We will keep informing.. 🙂