After a lot of working hours, finally I have a more or less defined chassis. It took me quite time to arrive to a design with which I felt satisfied.

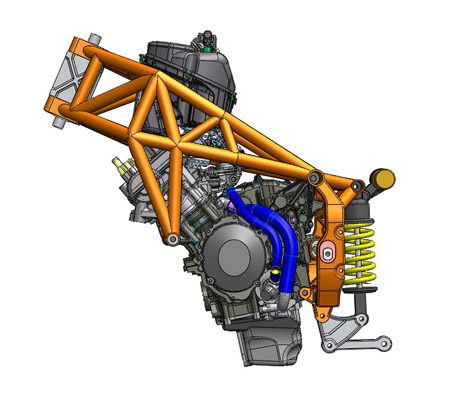

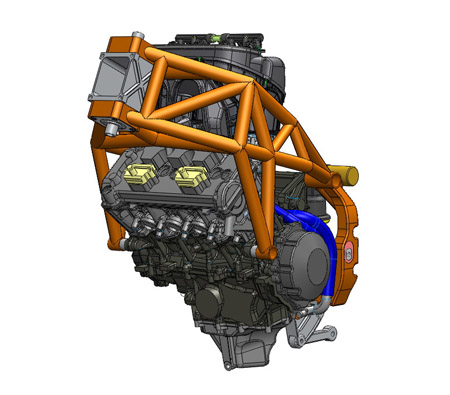

One of the particularities of this chassis is that he headstock is “stemless” type, this means it doesn’t have a steering axle that crosses it. In this way it is possible to improve a little bit the air flow that goes into the airbox.

In a competition in which all the engines are going to be the same, it seems interesting to try to achieve some small advantage in two areas that are directly related to the engine performance, one is air intake and the other one gasses exhaust.

If we look at the Moto2 bikes that have appeared till now, the FTR uses a stemless headstock and it is very probable that the Tech3 bike also uses it. It is not a new idea, some years ago bikes like the 95Racer and the Roadson (before known as Tucson) Superleggera BT 550 started using this solution.

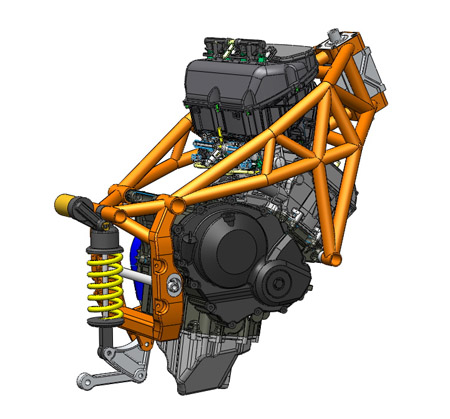

Like you see the chassis is a trellis, it doesn’t have any bent tube, all are straight ones. There are some tubes that could be bent ones, but I prefer to use straight tubes, in this way I can work with high strength alloys that do not allow bending. Regarding the tubes I am very satisfied because one of the technical sponsors of the project is Reynolds, a world leader fabricator of high performance steel tubes.

The parts that are located in the swingarm pivot area are made out of CNC machined steel.

The chassis is very low in the rear area. For the rear suspension I used the same linkage system that Yamaha is using in their Motogp and WSBK bikes. With this design I located the shock lower than in what is usual in most of twin spar chassis motorbikes. I tried to move the chassis and shock downwards in order to be able to locate the fuel as close as possible to the engine. In principle I don’t want to extend the fueltank a lot to the rear as it seems is the current trend in almost all Moto2 bikes we have seen till now.

I will keep informing about the project development.. 🙂

great project. i have been building and testing vacuum molding units to make parts for my cbr600rr. i am limited by the size of the plastic heating device (oven – don’t laugh) and basically wanted to know how u create the plastics for your project bikes. very cool how u used wood and foam to create mold form for tank.

thanks