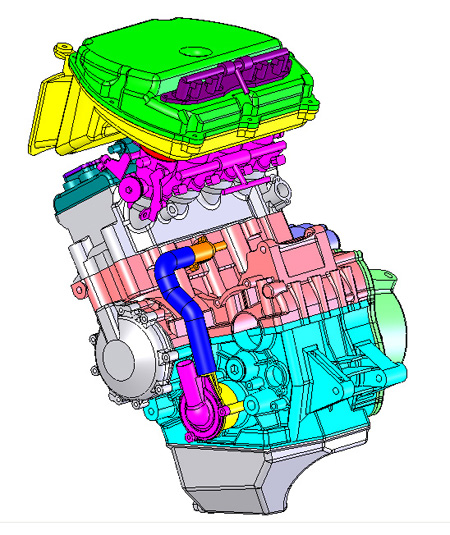

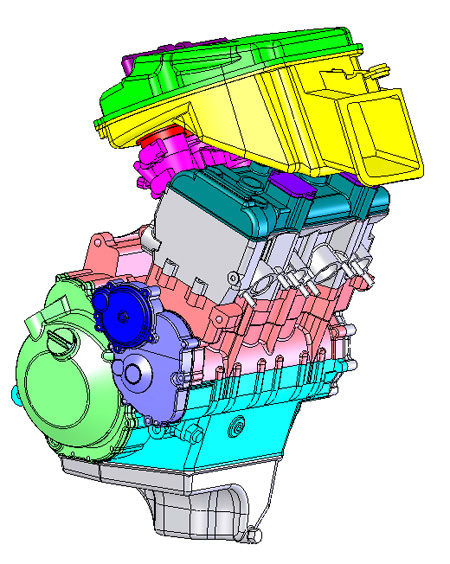

Last weekend I continued drawing components from the Kawasaki ZX6. In this case the water pump, the injection body and the airbox.

Of course we must design a new airbox, but I thought it was interesting to draw the ZX6 one in order to have a reference. Regarding this airbox, it catches my attention that the box has a quite small size, and the intake conduit a big cross section.

To design an airbox is not a simple issue. Pressure waves produced by the intake valves travel through it, and it is necessary to dimmension the box volume and the intake conduit (length and cross section) in such a way that the frequency of the pressure waves going through the airbox matches the opening frequency of the intake valves at certain rpm (normally top power rpm).

Also it is necessary to achieve a design that maximizes pressurization at high speed, in this way it is interesting that the air intake is located at a high pressure area in the bodywork, ideally in the nose like for example the KTM 250 GP or de Ducati MotoGP.

It is also necessary to try to achieve an air flow as much laminar as possible inside the intake conduit. Theorically the cross section of this conduit should increase as it arrives to the box, in order to reduce the air speed and increase it’s pressure.

I would like to find a collaborator with experience in CFD (Computer Fluid Dynamics) to study these questions, and analyze several virtual solutions before deciding the final design. So if you know about CFD and want to collaborate in this project, please send me an email.. 🙂

Continuing with the airbox design, other points to take into consideration are the box stiffness, that must be stiff enough to avoid beeing deformed by the pressure waves. Also it is important to make the box and it’s cover watertight, in order to avoid pressure losses.

There are also other issues that add extra complexity, for example the airbox must house the secondary injectors. In the ZX6 airbox they are located on the box cover.

Finally, the intake conduit design determines heavily the chassis design, but this is a subject for another post.

Like always you will find higher resolution images in the Flickr gallery.

we are a group of mechanical engineering undergraduates who are willing to take up the design and testing of air box as our project. We have the knowledge & access to our university’s CFD lab. We would delighted if you help us