The Morlaco was a project we carried out in our spare time, and in fact, as you know, it took us 20 years to finish the first prototype of this bike built around a Honda CBR954 engine.

A few weeks ago, we started working on the second version of the Morlaco (internally we call it M2). Our approach to this project is different, it is not a side project, we are dedicating resources to it and our goal is to have a running prototype early next year.

For the Morlaco 2 we are using an air-cooled, 2-valve, 1100 cc Ducati engine.

Surely, at first glance, many of you might find the choice of this engine somewhat strange. Why not choose a more powerful or modern engine?

We were tempted to create a superbike with a modern 1000 cc engine, but before making that leap, we preferred to take an intermediate approach by creating a bike that is very light and agile, achieving a good power-to-weight ratio. A bike that is easy and fun to ride fast.

The air-cooled, 2-valve, 1100 cc Ducati engine is highly valued by experienced enthusiasts with a deep understanding of the motorcycle world.

It is a classic and reliable engine that offers the rider an exceptional experience with its sound and low-end torque. Aesthetically, it is a very interesting engine, especially if you leave the belts and dry clutch exposed. It has a timeless design and there are numerous aftermarket parts available to improve its performance and reduce its weight. In short, it is a very versatile engine with great potential.

In the Ducati Monster 1100 EVO, this engine produced 100 HP. For track use, it is easy to prepare it to reach 125 HP, and even more.

And for “street” use, it is an engine that Ducati still uses today in the Scrambler 1100, which is up to date with emissions, complying with Euro5.

Like the air-cooled Buell engine we use in our BOTT XR1, these types of engines have “something” special, aesthetically, technically, in terms of sensations, and sound. They are engines with soul.

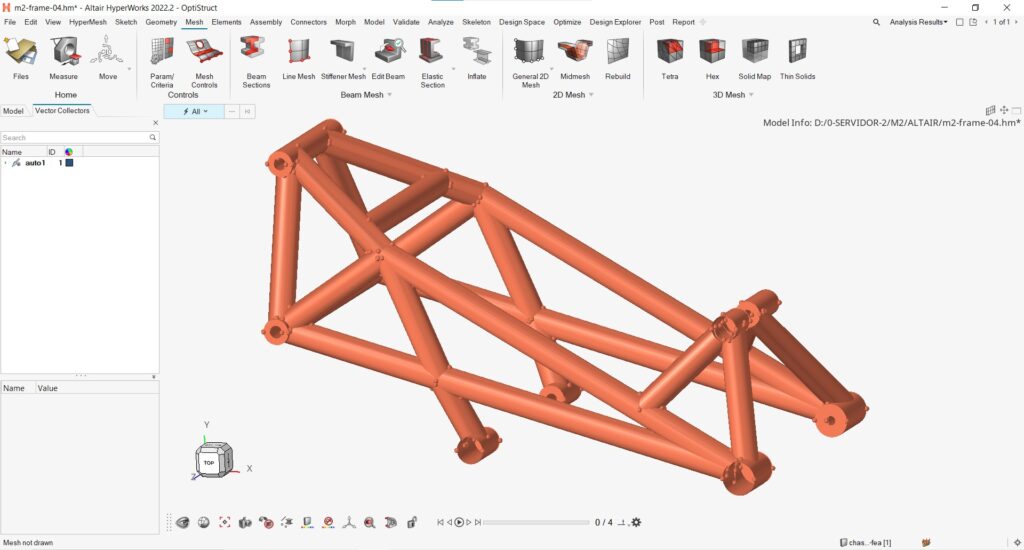

As you can see in the following image, we are working on a multitubular chassis made of straight tubes, a concept we have already used in other bikes, such as the first Morlaco or the BOTT M210 (the Moto2 bike we built in 2010).

Surely the chassis design will change as we progress with the bike design. These days we are working a lot with finite elements, using Altair’s Hyperworks software. This allows us to “test” various configurations of the tubes, as well as different materials, thicknesses, diameters, etc.

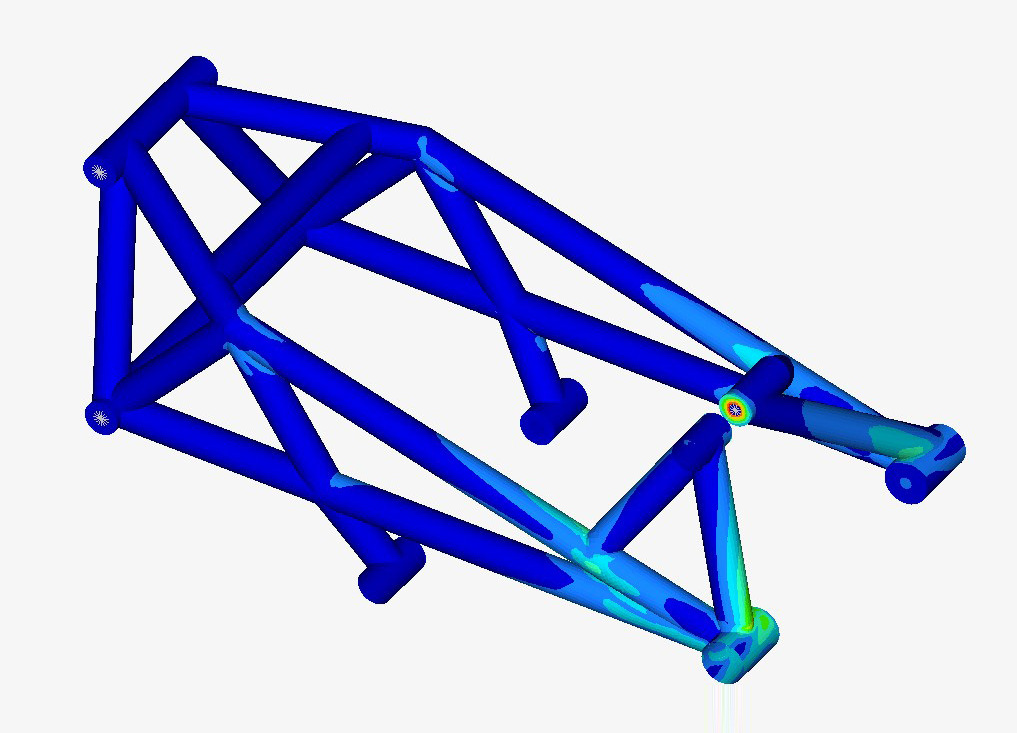

This model showcases the finite element analysis of stress distribution on the frame due to rear suspension forces.

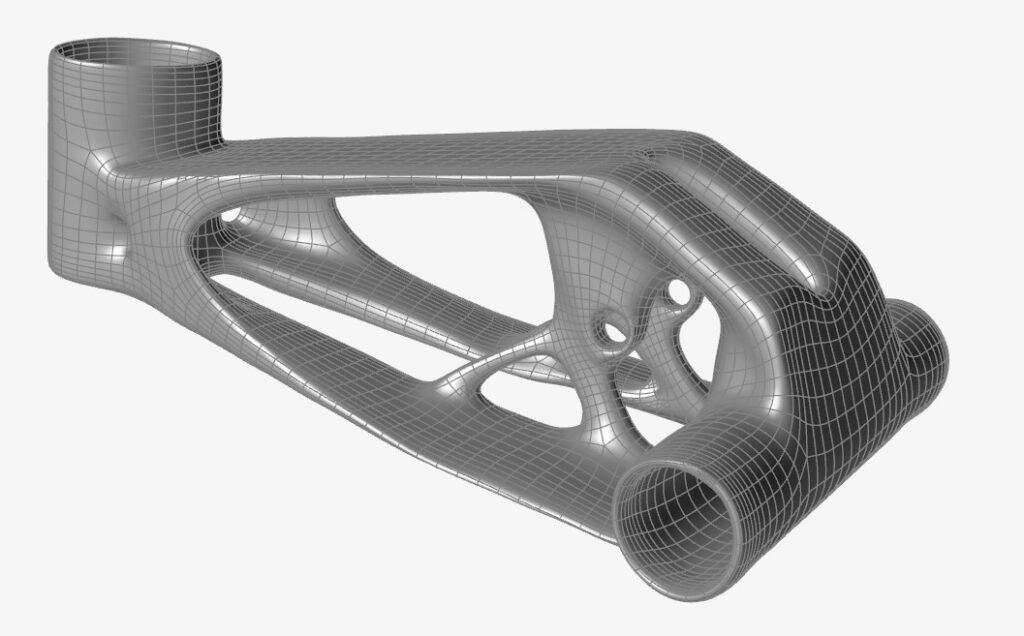

We are also carrying out topological optimizations to evaluate the possibility of manufacturing chassis parts through additive manufacturing (3D printing). For example, the following image shows the part that holds the triple clamp and the upper mount of the front shock absorber.

As for the front end, seeing the “work in progress” image of the complete bike, it can be deduced that the M2 has an alternative front end with an architecture very similar to that of the Morlaco 1. For the fork, we are working on several ideas, which we will show you in future posts as we progress with the design.

As for the rear end, for now, we are keeping the single-sided swingarm of the Monster 1100, although it is likely that in the future we will end up developing our own swingarm and rear suspension system.

The wheels are Rotobox, a brand we have worked with since our participation in Pikes Peak in 2017. Specifically, these are their Bullet carbon wheels.

Stay tuned! In the coming days, we will be updating you on the progress of the project, as well as the tests we are conducting with the Morlaco 1.

How cool is that! I used to work for Britten so love a FFE (Funny Front End)

I’m quite familiar with those big Ducati 2V engines too. Love them.

Following with interest.

Hello Hamish, thank you for your comment. Wow, working for Britten must have been an amazing experience! Of course, Britten has been a huge source of inspiration for us. There are several posters of the Britten in our workshop. 😊

Those Ducati air-cooled engines have a special place in our hearts too. Thanks for your support!

If I had the ability it is precisely what I’d build. Please don’t allow the development to compromise from tubular steel and 1100 engine. Like to see tubular swing arm too. Good luck, I’m starting to save my pennies

Hello Stuart, appreciate the feedback! We’re committed to maintaining the tubular steel and 1100 engine. Regarding the swingarm, let’s see what we can do!

Thanks and good luck with saving up! 😊

Loving the concept as always if it has a FFE then count me in looking forward to seeing more progress images and like the sound of a V twin so top marks so far 👍

Hello Paul, thank you for your comment. Glad you like the concept! The FFE and V-twin are central to our vision for the M2. We’ll be sharing more updates and images as we move forward. Stay tuned!