Pikes Peak International Hill Climb is an event in which you can race only by invitation. The total amount of vehicles (cars plus motorbikes) that race in the PPIHC has been limited to around 100.

The registration entry deadline was January 27, 2017. After this date, the PPIHC Race Committee selected the teams that were invited to race, and on February 17 they notified the competitors if they were invited to participate in the race.

Although we didn’t have any specific reason to think that we were not going to be accepted, it is true that the 17th of February we breathed a sigh of relief when we received an email from the organization confirming that we were in. On February 20, they published the official list of competitors invited to participate in the race.

Our rider for this race is Travis Newbold, a local rider that has raced in Pikes Peak 8 times, winning in different categories, and finishing second in the motorcycle class in 2015 when he was riding the EBR powered Ronin bike.

We are really happy of having Travis as rider for Pikes Peak. With his experience and speed on this race, we think that he is 100% capable of riding as fast as any other rider. The key-point is to see if we will be able to give him a good bike for the mountain. Taking into account that we have no experience there, and no experience (by the moment) with the XBRR engine, it is clear that this is not going to be an easy task for us.

Another great point of having Travis with us, is that he lives in Arvada, Denver, where he runs “Newbold’s Motorbike Shop”, a motorbike workshop which is at one hour by car from Pikes Peak. This will make everything much easier from a logistics point of view, because we will have a place where we can ship the bike from Spain, and also a workshop that we can use as our operational base if we need it.

Regarding sponsors, during the last weeks we got some very interesting companies joining the project. By the moment, apart of our main sponsor Kriega, we count with the support of Rotobox, Global Racing Oil, Continental, EFI, Ceracarbon, Totimport, Husmee, Newbold’s motorbike shop, Technical Composites, Motorbike magazine and Sideburn. In next posts we will explain what each of these sponsors is adding to the project.

Regarding Kriega, they have launched a great line of products with the Bottpower image, which are already in pre sale in their website. All the money coming from the sale of these products will go directly to our team to finance our Pikes Peak project. We encourage you to buy one of these top quality products if you want to help us to carry out this project!

Now let’s see how is everything going on regarding the design and construction of the BOTT XR1R that will race in Pikes Peak.

We still have many things to do in order to have the bike built on time for doing several tests before going to Colorado. We have many fronts moving ahead at the same time, so if everything goes OK, we should have it built in a few weeks. Anyway I am sure that we will keep working on it till the very last moment before shipping it to Colorado.

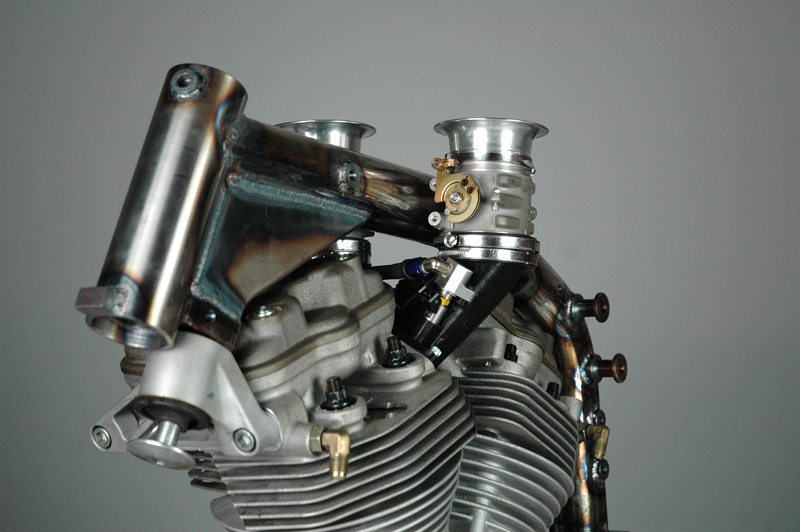

In previous chapter, we had scanned the original XBRR engine intakes to modify them to allow our frame to run between them.

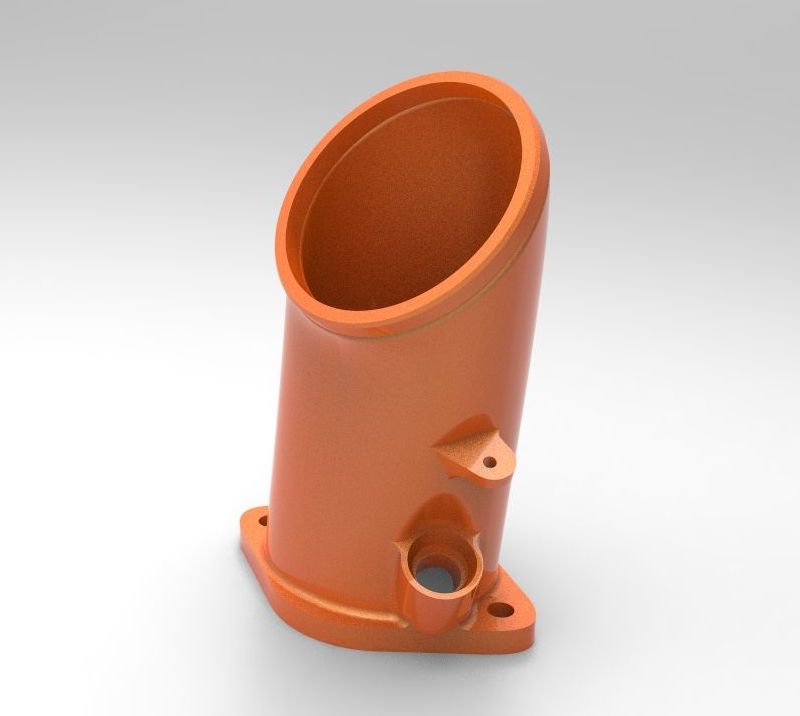

Next image shows the design of the new intake. The most important thing has been to keep the injector in the same position it had in the original intake.

Once we had the new intake designed, we printed 2 units in plastic. These printed intakes are not functional, but they served us to check that everything was correct before milling the definitive ones.

Here we have our 3d printed prototype next to the original magnesium one:

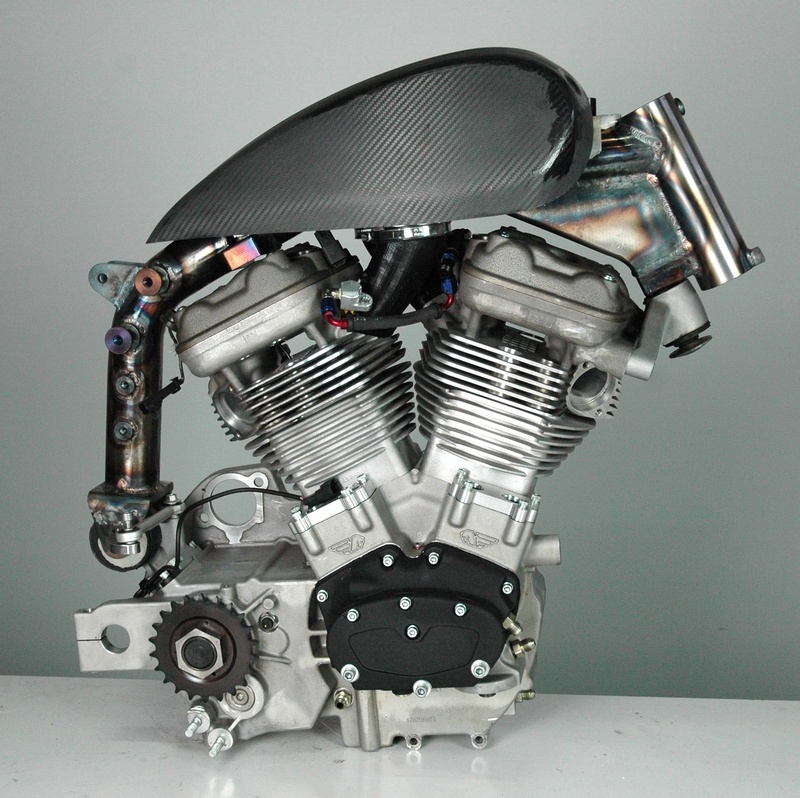

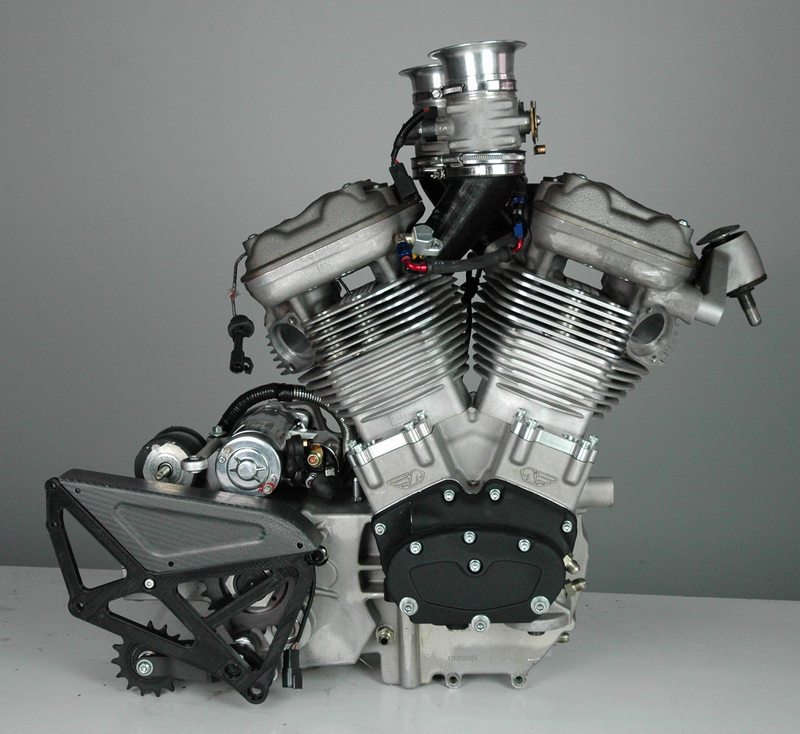

Next pics show the 3D printed intakes mounted in the engine, with the frame running between them. Fortunately, everything fits as planned, and we already ordered the milled intakes.

We also mounted the top part of our XR1 carbon fiber fueltank, just to check that the injection body and velocity stacks fit properly inside it. As you know, the Pikes Peak race bike will use only the lower tanks, with the top one acting as an airbox. Everything was OK and now we must design the lower part of the airbox and the intake conduits that will feed the airbox with fresh air.

We also mounted the subframe and the electric wiring loom of the XBRR, just to check that we didn’t have any length problem with the wiring.

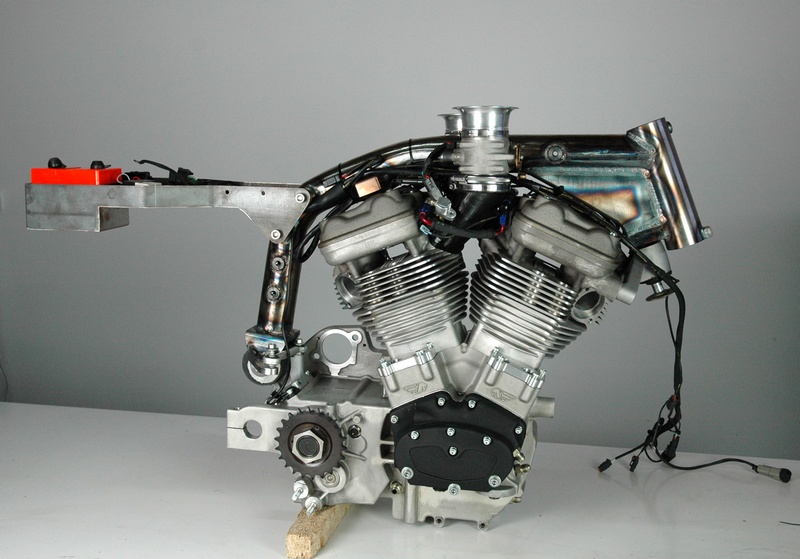

The XB and XBRR engines share the same front and rear mounting points, but the rest is quite different. We had to design a new right side footpeg, because the one we use on the XR1 doesn’t fit in the XBRR engine.

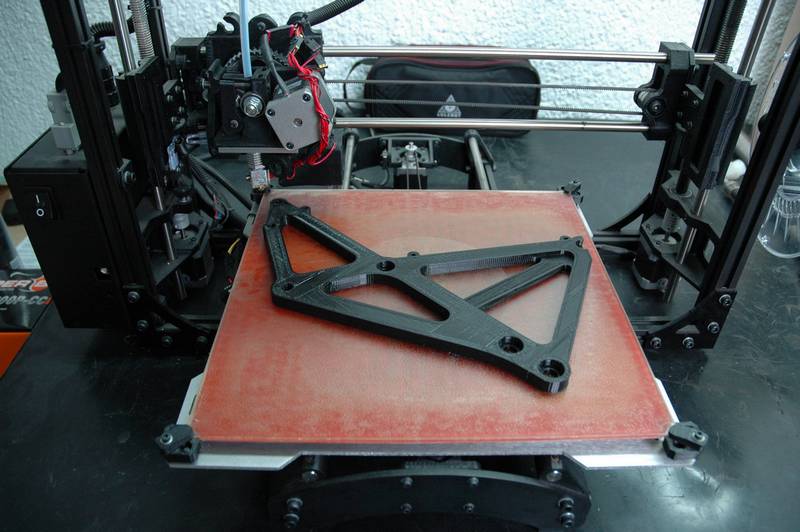

Because we do not have the XBRR engine in CAD, we are using the 3D printer more than what is usual for us. Before machining the footpeg in aluminium, it is well worth to print a prototype in plastic just to check that everything fits properly.

Here you have the prototype still on the 3D printer:

And here mounted in the engine:

From now on we expect to move the project forward in a faster way, so we will update the blog more often.

Great progress, David. Love the intakes. All the best of luck to the team.

Thank you Bob! 🙂

Many things of your to do List…

Good Luck and always a handfull Asphalt under your tires…

Greetz

Andy

Thank you Andreas.

Yes, the list is veeeery long, but the important thing is to keep moving forward, with everything under control and to arrive on time to the shipping day. 🙂

So excited by this new project !

Congratulations :))

We are really excited too. Thank you! 🙂

Hehehe..really interested to see if Travis can run up the hill and return the bike in piece, as it happened in record run Ronin machine in finishing celebrations.

Hi SiimR, thank you for your comment. We will see… 🙂

this is a real pleasure to follow your evolution and pikes peak project.

great job, david

Hi Sami, thank you! We will see how great the job is once we are in the mountain… 😛

Nice work! Really interesting see the process of working out the details. Could you in a future post show/explain how air is flowing to 2 stacks. I see the gas tank on top and not sure how you get air in.

Hi Charlie, thank you for your comment. We will explain it in following chapters. Basically the bike will have 2 external conduits that will take air from the front of the bike and will introduce it into the airbox.

looks great, can’t wait to see if you guys can give my buddy Jeff Tigart a run for his money

Hi Bill, thank you for your comment. This year we only plan to race one bike. Of course we will try to achieve a good result, but our main aim is just to learn and acquire some experience in that race with those so special conditions.

All the best!

Hi David, glad the project is coming along so well! I was curious if you plan on utilizing the factory Buell eight piston caliper, or if some Brembo parts are in order?

Hi Bryce, thank you for your comment.

We will not use the Buell brake system, because the carbon fiber rims that we are using doesn’t allow to mount the perimetral brake disc.

So yes, we will use Brembo calipers. 🙂

Premium Brembo brake components are always a safe bet. What are you considering in terms of suspension units? I would consider the Showa BFF or Ohlins FGR series some of the better production forks on the market currently.

Hi Bryce, we are using an Öhlins fork with Öhlins TTX 25 cartridge. This fork has been built by one of our sponsors, Ceracarbon. It has a carbon fiber inner tube, with an outer ceramic coating. This saves 1.5 kgs compared with the original steel tubes, and the ceramic coating has less friction than titanium nitride.

http://www.bottpower.com/images/170319-fork-01-1800.jpg

Full explanation in the next blog post. 🙂