In this post, we will explain how we have built the Morlaco fuel tank.

On the one hand, we decided to make the outer carcass 3D printed in plastic. In this way, we save time and money without having to make any mold. Optimus 3D printed the parts. In order to make the printing process cheaper, we divided the carcass into 5 parts, that would be glued together later on.

On the other hand, we decided to bet on a very safe technology that nowadays is mandatory in most car races. Racing cars use fuel cells, which are flexible bladders, custom-built with composites. These bladders are the fuel tank and they must comply with the FIA safety norms.

The advantage of the fuel cells over traditional sheet metal fuel tanks is that they have a much bigger impact resistance. They also are much less prone to having problems due to cracks or pinholes.

In the past race cars used sheet metal fuel tanks, but fuel cells become mandatory many years ago because they increase safety by a big factor. It is curious that the motorcycle racing world has not decided to take that step yet.

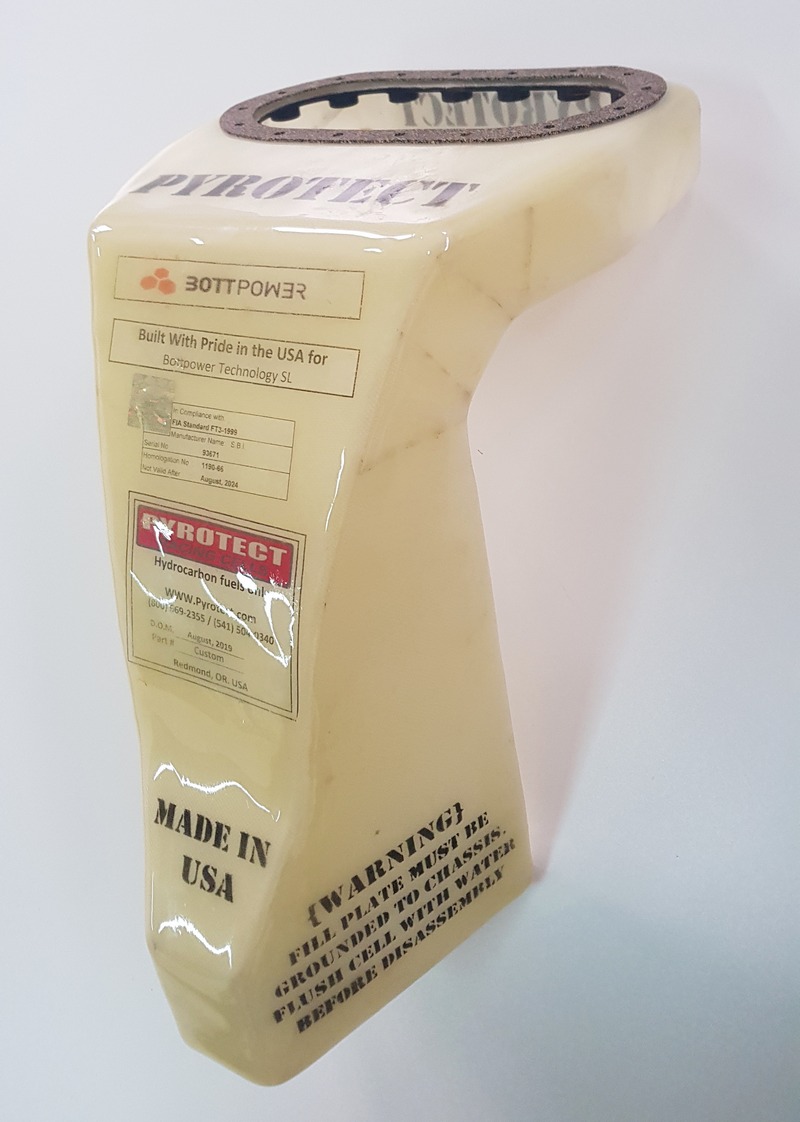

In our case, we have used a custom made fuel cell for the Morlaco, fabricated by Pyrotect, a top specialist from the US. This fuel cell complies with the FIA FT3 norm.

Also, we also decided to use Explostop, a Spanish product that reduces almost completely the possibility of having an explosion in a crash.

We explain it to you in a more detailed way in the next video.

See you soon! 🙂

Hi, As i am a Mechanical tradesman (Fitter & Turner), i very much like the idea and process you guys have proposed. The shape is good for C of G, and not changing very much as the load diminishes.

Thank you for your comment, Stephen. 🙂

Yes, we think that for low production 3D printing is a very interesting process. And the Pyrotect bladder, together with Explostop makes the tank much safer. And safety is important. Regarding CoG, you are correct, the tank design was intended to avoid weight distribution changes as it empties.

¿Se podría llenar el depósito de cualquier moto con “explostop”?